Gibson Centri-Tech

Post from Cast Metal Times April/May 2002

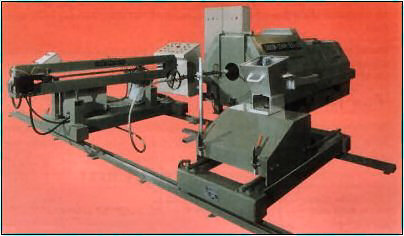

Gibson Centri-Tech Ltd is recognised as one of the world’s leading exponents of centrifugal casting technology. With more than 30 years experience, the company has remained at the forefront of developments in the design and manufacture of centrifugal casting systems, approved to ISO 9001:1994.

Gibson Centri-Tech can design both horizontal and vertical axis machines capable of producing components in most metals and alloys

Gibson Centri-Tech’s recognised strengths – experience, innovation and quality – are combined with a wide diversity of foundry knowledge enabling the company to fully understand and fulfil customer’s needs wherever they are located in the world.

Gibson Centri-Tech can design both horizontal and vertical axis machines capable of producing components in most metals and alloys weighing anything from a few grammes to several tonnes for the most cost effective implementation of customers requirements.

The company can also offer a full plant layout and foundry design service using the latest technology.