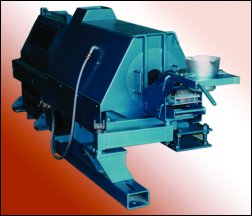

This is the most popular series of horizontal machines manufactured by Gibson Centri Tech. Five standard basic sizes are offered with an extensive selection of variations to suit individual specific requirements. Single or twin head machine versions are available.

The Alpha-Gyra Machine

AGE 1 Casting Machine

This machine is designed and manufactured to meet the requirements of one offs, jobbing, medium to mass productions of cylinder castings for diesel and petrol engines, gear wheel blanks, high duty bushes for automotive and engineering duties and pump sleeves, in high duty nickel alloys

The Alpha Uni-Gyra Machine

AU1 G/W Auto Spray System

Is a high duty version of the Alpha-Gyra Machine having high speed capabilities with a range of optional production items including programmable control unit, automatic mould coat spraying, and mechanical casting extraction, making it more suitable for mass production duties. The Twin head machines are best employed for medium to long production runs of cylinder liner castings of maximum 500mm internal diameter.

AU 3 Casting Machine

Main Features

- Moderate capital cost.

- Simple to install & operate.

- Ready for use on connection of supply services.

- Simple to maintain.

- Low noise and vibration levels.

- Flexible.

- Suitable for both “jobbing” work and high production of standard components.

Typical Centrifugal Castings

Horizontal Shaft

Alpha Gyra – Uni Gyra

- Bushes

- Cylinder liners

- Flanges

- Seal Ring Castings

- Slip Ring Castings

- Pump Sleeves

- Bearing Case Castings

- Pipe Fittings Valve

- Seat Castings

- Gear Wheel Blanks

- Bushes for bearings & General Engineering Duties

- Small Stern Tubes

- Pressure Tight Castings

- Ball Valve Castings

- Reactor Seal & Guide

- Sleeve Bearings

| Model | Casting min & max mm | casting length mm | Total load including mould |

|---|---|---|---|

| Alpha 1 | 50-550 | 600 | 600kg |

| Alpha 2 | 70-650 | 750 | 1300kg |

| Alpha 3 | 100-750 | 900 | 2000kg |

| Alpha 4 | 100-900 | 1050 | 3000kg |

| Alpha 5 | 200-1000 | 1400 | 5000kg |

Other variations available on request, weights and sizes guide only please refer to load speed chart