Below are some of the varied technical questions which receive from some of our customers. Our technical team are experts in the design and building of our centrifugal casting machines. Our Team are always on hand to provide support and guidance. You can contact our sales team on sales@gibsoncentritech.co.uk with all of your Centrifugal Casting questions.

“Should I use a Horizontal or Vertical Centrifugal Casting Machine to manufacture my product?”

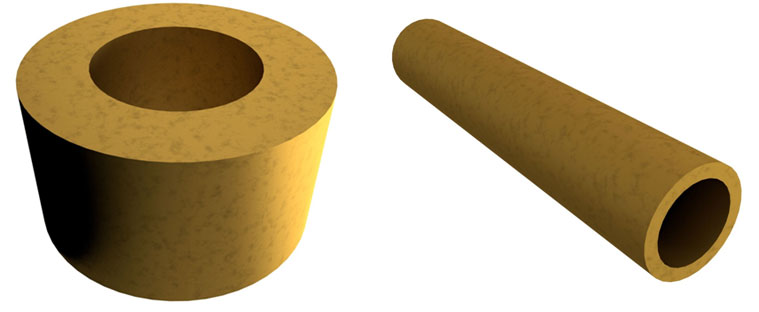

The general rule is if the diameter exceeds the length Vertical centrifugal castings are more suitable, however there are exceptions, solid castings can only be made vertically, some alloys are more suitable for vertical centrifugal casting and sometimes people just prefer either the horizontal or vertical method.

The general rule is if the diameter exceeds the length Vertical centrifugal castings are more suitable, however there are exceptions, solid castings can only be made vertically, some alloys are more suitable for vertical centrifugal casting and sometimes people just prefer either the horizontal or vertical method.

“What information do you need to quote a suitable Centrifugal Casting Machine?”

We will send you a basic questionnaire which will detail all required fields, but principally the information we require I/D, O/D, length, material and quantity of castings you wish to produce.

“We have no experience in Centrifugal casting and are worried about our ability to manufacture a successful product.”

Gibson Centri Tech can help you with every stage of the process, from guiding you with the selection of your equipment, we can also offer layout drawings of your foundry as well as installing the equipment and providing ‘know how’ training.

“What are the latest developments in Centrifugal Casting machinery?”

Gibson Centri Tech believe in continual improvement in our equipment, while the designs can trace their roots back thirty to forty years they have been endlessly improved to meet modern safety standards while embracing the latest technology. The level of automation has increased and where appropriate incorporating Servo drives and robotics.

Gibson Centri Tech believe in continual improvement in our equipment, while the designs can trace their roots back thirty to forty years they have been endlessly improved to meet modern safety standards while embracing the latest technology. The level of automation has increased and where appropriate incorporating Servo drives and robotics.

“We are an automobile parts manufacturing company. We are producing Centrifugal Castings for Cylinder Liners. Please advise on which mould coating would be most suitable for our Production Needs.”

Gibson Centri Tech produce a range of Silica and Alumina coating however if we feel our coating is not the best product for you we will recommend an alternative supplier. Over the years Silica coating has been a popular product for use in the manufacture of cylinder liners and is still use extensively, however nowadays with modern Health and safety requirements the customer would need to check local regulations before using this product and ensure suitable dust extraction and PPE is used.

Gibson Centri Tech produce a range of Silica and Alumina coating however if we feel our coating is not the best product for you we will recommend an alternative supplier. Over the years Silica coating has been a popular product for use in the manufacture of cylinder liners and is still use extensively, however nowadays with modern Health and safety requirements the customer would need to check local regulations before using this product and ensure suitable dust extraction and PPE is used.

“Do we need a different machine for Ferrous and Non-Ferrous Centrifugal Castings?”

The short answer is no, the machine does not mind which material is being poured there can be differences in the mould design depending on the liquidus temperature and wall thickness of the casting being produced.

“We are trying to improve our production range of centrifugal rolls. Currently we are producing static ductile iron and steel rolls. Please advise the best centrifugal casting machine and procedure we would need to approach to achieve our desired results.”

We would firstly propose to initially offer a preliminary technical study covering the following points:

We would firstly propose to initially offer a preliminary technical study covering the following points:

- Review the selected cast products required to establish their suitability for centrifugal casting and equipment type.

- To establish suitable equipment and moulds to produce the required casting.

“We have recently purchased one of your GML 2.5 machines from an old customer of yours. The machine is over 20 years old and we are considering the possibility of refurbishing this machine. Is this something that you offer?”

We have over the years refurbished many machines to bring them back to “as new condition” The refurbishment of the machine will include the following:

We have over the years refurbished many machines to bring them back to “as new condition” The refurbishment of the machine will include the following:

- Inspect the machine

- Clean, shot blast and paint

- Replace guards and interlocks if required

- Replace Bearings

- Rewire

- Upgrade control panel

- Inspect and test

“We have on site an Alpha 1 Centrifugal Casting Machine which we purchased from you 5 years ago. We are considering having an annual service on this machine, is this a service that you can offer?”

We do offer annual servicing on all of our centrifugal casting machines. We believe that it is beneficial that to ensure that your foundry equipment is in the best possible condition. With annual machine servicing planned maintenance will help to reduce machine downtime and will increase the life of the equipment.

We do offer annual servicing on all of our centrifugal casting machines. We believe that it is beneficial that to ensure that your foundry equipment is in the best possible condition. With annual machine servicing planned maintenance will help to reduce machine downtime and will increase the life of the equipment.