Why Choose Centrifugal Casting?

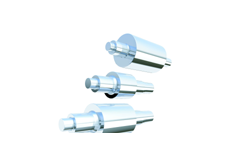

The practice of centrifugal casting involves using a centrifugal force, the force when a body is subject to a high velocity spinning action to exert pressure onto molten metal as it is poured into a die, this method has a number of advantages over traditional static die-casting methods.

Centrifugal force brings about an even distribution of the metal and forces gases and other impurities out of the critical section of each casting, resulting in consistent, high quality output with superior physical properties.

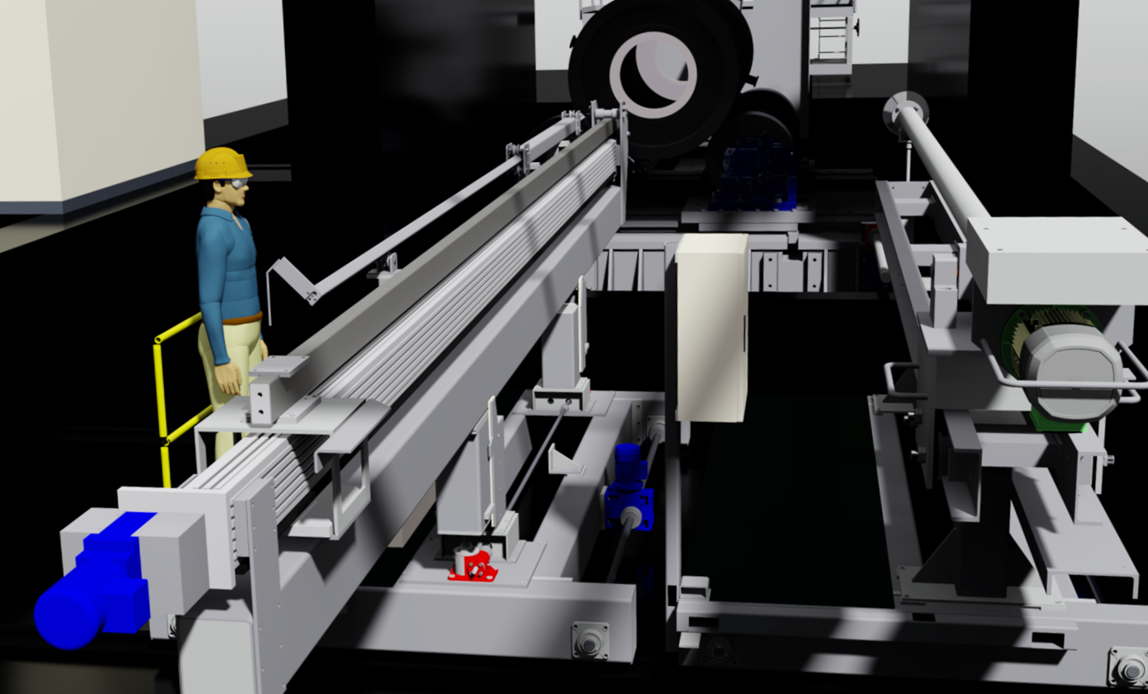

By refining the operating techniques and upgrading it’s programmable machines with a number of innovative features, Gibson Centri Tech Limited has improved still further the efficiency and productivity of a well established process.

Other advantages of Centrifugal Casting are:

Reduction of equipment cost

Centrifugal Casting offers a substantial saving on capital equipment when compared to forged products.

Reduction of Manufacturing Costs

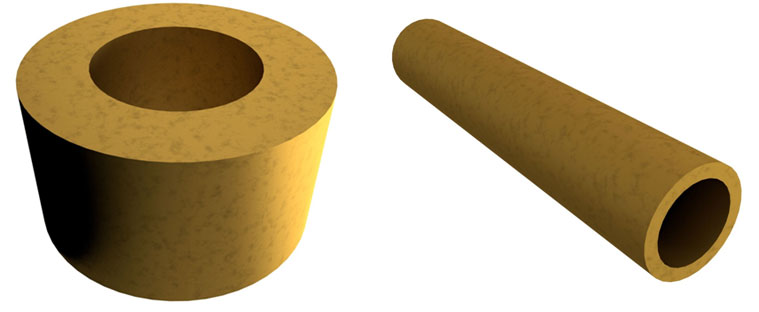

The uniformity resulting from the centrifugal casting process means that machining time and material waste are significantly reduced. Blowholes, sand residue, hard spots, cavities and porosity are virtually eliminated.

Extensive Life

Due to the finer grain and denser structure of parts with centrifugal there is an increased usage life, greater endurance and impact without fracturing.

Fewer Castoffs

The force used to distribute the molten metal as it is poured is so strong it displaces the lighter oxides and impurities to the centre of the hallow cylinder. It is then easy to remove these impurities.

Flexibility

The centrifugal process allows economical production of a wide range of sizes, shapes and quantities.

In short centrifugal casting results in longer life, reduced rejects, reduction of manufacturing costs and production flexibility.