Tags : Carousel machines centrifugal casting machines

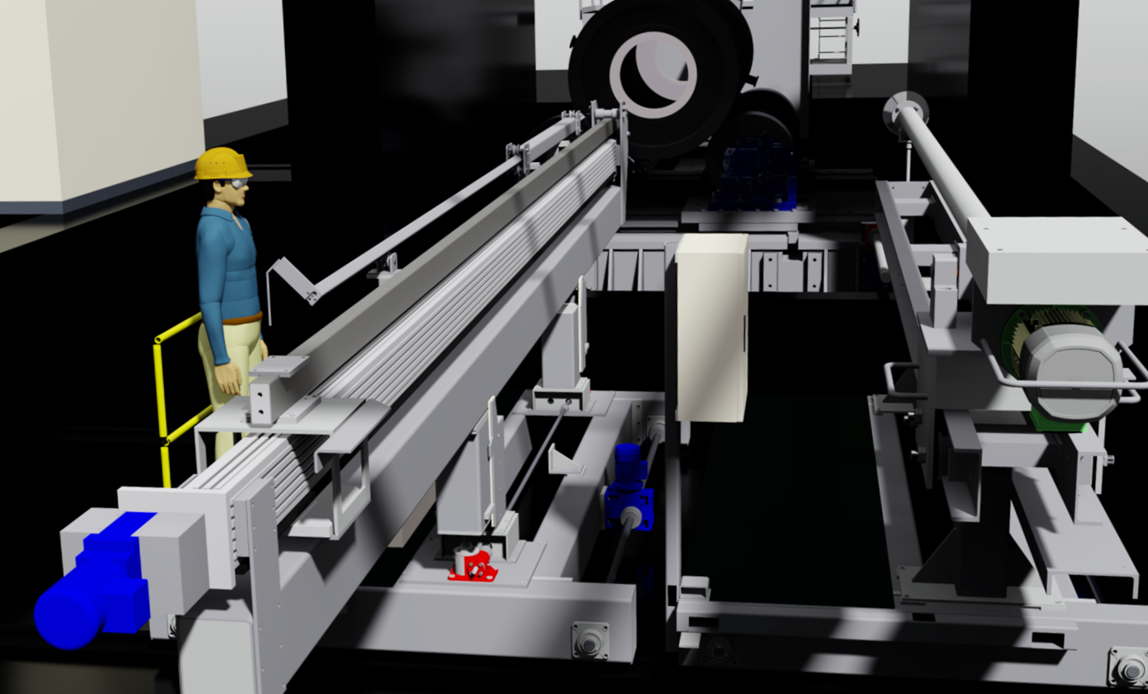

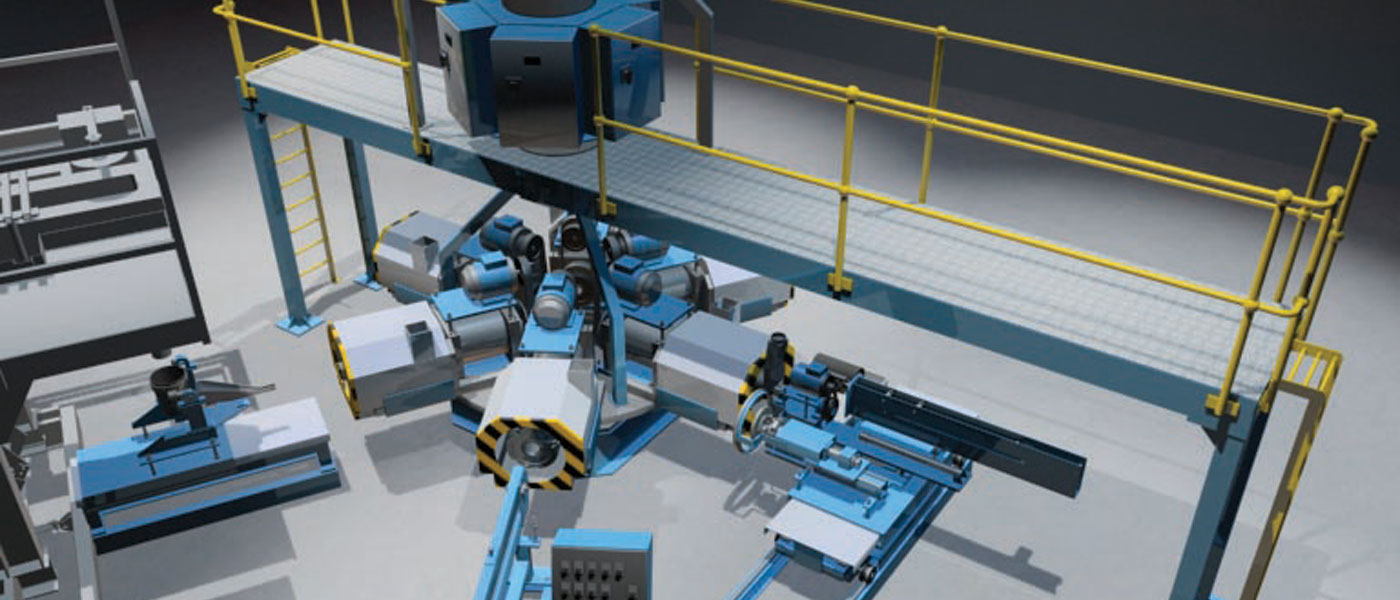

One of our high-profile horizontal machine ranges is the Carousel (Multi- Head) machine. The carousel machine range is designed and manufactured to meet the production requirements of medium and large OEM producers of cylinder liners. These machines can produce single liners or multiple lengths depending on size and type.

Profiled wet and diesel liners are usually produced in single pieces. Smaller automotive low profile wet or “cast in” block, these liners can be cast in lengths of four depending on the size. The carousel machine offers a highly versatile alternative to conventional tube type machines.

The machines are fully automated and can employ either wet or dry coating methods. One of the key elements of the carousel machine is the consistent production, the critical points are monitored and controlled throughout the production process. These include pouring temperature and die temperature. The latest control and instrumentation technology are incorporated into the equipment.

Production rates are dependent on wall thickness of the casting. Typically, a six head unit can consistently cycle at 45 seconds producing four cylinder liners per casting, giving an hourly production rate of 320 liners.

Several versions of this machine are available to suit the production, budgetary requirements and size or type of castings being produced. Six, eight, ten or twelve head models are available with various options, subject to the customers requirements. Variants of these machines can produce thin wall liners at a rate of one every 35 seconds.

Several versions of this machine are available to suit the production, budgetary requirements and size or type of castings being produced. Six, eight, ten or twelve head models are available with various options, subject to the customers requirements. Variants of these machines can produce thin wall liners at a rate of one every 35 seconds.

The reliability of these machines has been proven in the field. In the last five years we have had repeatable orders from customers in India and the USA who have purchased various versions of this machine range for their facilities.

This simple to operate but robust design provides greater reliability without undue sophistication.