Gibson Centri Tech Limited Additional Products

In the addition to the supply of equipment and parts Gibson Centri Tech Limited also provides a broad range of complementary services that includes:

- Plant layout

- Equipment Installation

- Full Technical Support

Applied to projects both in the UK and overseas, this comprehensive capability has continued to prove it’s worth providing cost effective solutions to casting problems encountered by foundries worldwide. Gibson Centri Tech Limited uses the latest techniques to design centrifugal casting machine systems for business in many industries across the globe; our engineers solve even the toughest design problems quickly and efficiently using the latest techniques.

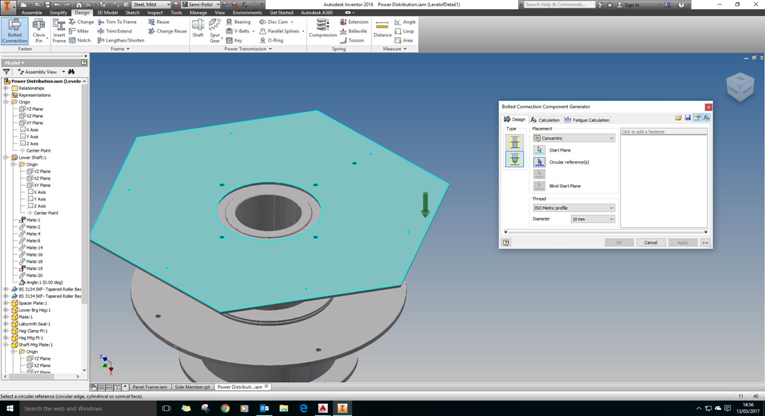

Our Engineers complete 3D designs of every customers centrifugal casting machine before any metal is cut. This allows design reviews to be presented in an easy to understand format, allowing a rapid and inexpensive development process. Gibson’s customers can then realistically visualise all components parts prior to machine manufacture, giving them a better understanding of each machines capabilities.

Gibson Centri Tech Limited utilise the customers requirements, objectives and design constraints to provide the right automation solution for every customer. We offer a large range of solutions from prototypes, fully manual stand alone machines, manually loaded semi automated machines to fully automated stand alone and integrated factory systems employing innovative process automation technology.

Our Engineers are experts in the design and building of Centrifugal Casting Machines with electric, pneumatic, hydraulic and mechanical drive mechanisms for virtually any project.

Custom features are also available on Gibson Centri Tech Limited machines; they can be equipped with custom features such as SCADA (Supervisory control and data acquisition). As with all our automation systems, the Gibson Centri Tech Limited systems are custom designed and built to fulfil the customers project requirements.