Gibson Centri Tech Limited – Technical Assistance

Gibson Centri Tech Limited can off a range of services to aid the customer in their successful production of Centrifugal castings. We will advise from start to finish on the process, because even the smallest parameter change can lead to a successful casting. Our services range from support in the following areas and we can even offer technical assistance using third part equipment:

Equipment Selection

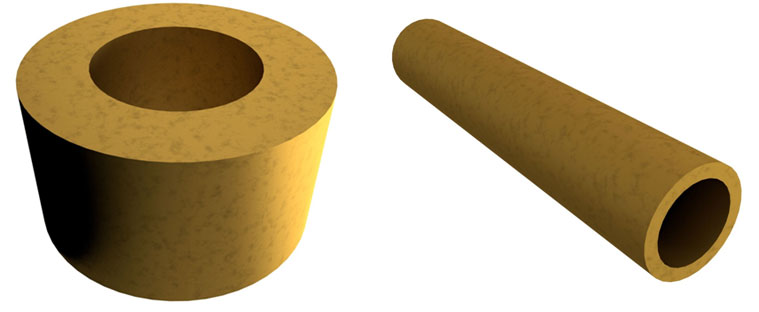

New or existing, are you using the correct type of equipment to successfully produce your casting? For example some types of castings can only be successfully manufactured on a vertical style machine. You also need to ensure that the mould is safely and securely supported to ensure that there is a limited amount of vibration.

Equipment Selection:

New or existing, are you using the correct type of equipment to successfully produce your casting, for example some types of castings can only be successfully manufactured on a vertical style machine. You also need to ensure that the mould is safely and securely supported to ensure that there is a limited amount of vibration.

Mould Pre-heating and temperature:

This is a critical area for centrifugal casting production as different alloys and different coatings require temperature adjustments and most importantly you must ensure that the mould is free from moisture. Correct temperature will reduce or eliminate pin holes in castings as well as aiding metal flow.

Housekeeping:

Mould cleaning is an area which can give you instant improvements and scrap reduction, but it is sometimes one of the most neglected areas of centrifugal casting production. Moulds internally should be free from carbon deposits, old mould coating and oil as these can all lead to coating flaking off and subsequently scrap castings. Care should also be taken with the pouring bush horn to ensure that it is free from metal splatter or loose refractory as these can be deposited in the centrifugal casting.

Mould Spraying Equipment:

Automated spraying machines if set up correctly will accurately and evenly deposit mould coating on the mould surface offering full repeatability. Automated spraying allows customers to reduce machining allowances speed up production, reduce scrap and stuck castings. Hand spraying will always be required for low volume and complex shapes, having the right equipment with correct parameters set is vital in achieving accurate spraying patterns.

Mould Coating:

Coating selection, there are plenty of different coatings available on the market we manufacture two ourselves Alumina (Trigex) and Silica (300/3) which has been successful with different alloys over many years, but we will use your coating selection or if no preference the best coating for your production which we will then optimise for your castings.

Casting Extraction:

Push or pull system, there are many different ways to extract castings a lot depends on the size and quantity of the casting being produced. If a casting fails to extract you need to investigate the cause as it might not be the equipment it could be anyone of the processes leading up to extraction.

Casting Handling:

This area can save a lot of time, a lot will depend on quantity of castings and what further onward processing is required for example a robot could automatically load castings onto a conveyor of an in line shot blasting unit or even as simple as a gravity conveyor